Lifecycle Engineering Operation

Services > Lifecycle Engineering Operation

Lifecycle Engineering operation

Lifecycle Engineering Operation

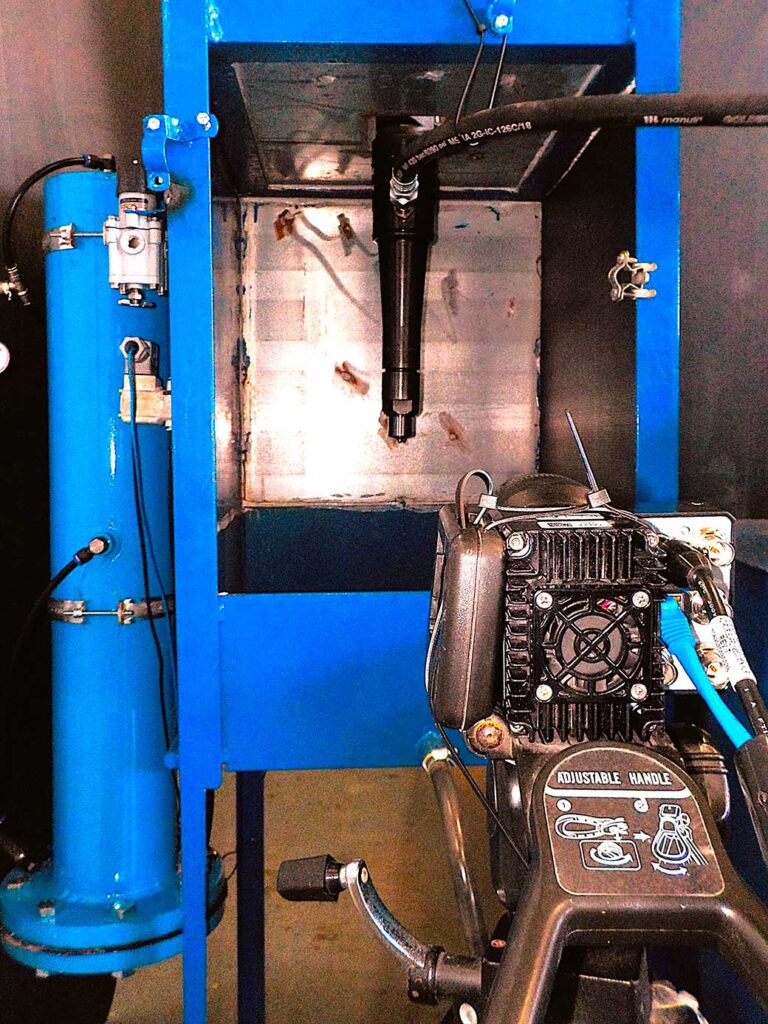

The Lifecycle Engineering operation of VTS is focused on the analysis and optimisation of system and component performance.

Thanks to advanced calculation methods (FEM, CFD, functional testing) and structural, thermal and dynamic validation procedures, VTS ensures solutions with high efficiency, durability and sustainability.

Each project is developed to maximise operational performance, reduce operating costs and guarantee compliance with international safety and quality standards throughout the operational life of the machinery in question.

VTS has the expertise, equipment and certifications necessary to carry out the following activities on-site, both on-shore and off-shore:

Lifecycle Engineering operation

Non Destructive Testing (NDT)

Non-destructive testing comprises a series of inspection and testing techniques that enable verification of the integrity of materials, components or structures without damaging them or compromising their performance.

- Magnetic Particle Inspection: technique used to identify surface discontinuities in ferromagnetic materials.

- Liquid Penetrant Testing: methodology for detecting surface defects through the use of liquids that penetrate discontinuities.

Lifecycle Engineering operation

Condition Monitoring Tests for Dynamic Diagnostics

Condition monitoring tests are employed to assess the health status of machinery and plants without interrupting their operation, thus enabling so-called dynamic diagnostics:

- Vibration Analysis: (in accordance with ISO 20816)

- Mechanical Fault Diagnosis: identification of imbalances, misalignments, bearing wear or gear problems.

- Preventive Monitoring: early detection of anomalies to prevent failures.

- Performance Optimisation: reduction of abnormal vibrations and improvement of system efficiency.

- Infrared Thermography: detects variations and temperature gradients on the surface of mechanical components in operation, therefore without interrupting the operational process, indicating potential anomalies or problems.

- Engine Parameter Diagnostics and Management with real-time monitoring Hardware and Software kits

- Megger Electrical Insulation Verification: Used to test electrical insulation by means of resistance meters. The test is carried out with equipment compliant with TUV protocols, applying potential according to reference standards IEC/EN61557-1 and IEC/EN61010-1

GET IN TOUCH

Need High-Performance Marine Solutions?

Our engineering team is ready to support your next ship repair, refitting or power system integration from design to execution.